We are a calibration laboratory with a long tradition, which is accredited by the Czech Accreditation Institute in the fields of length and plane angle calibration according to ČSN EN ISO/IEC 17025:2018. Calibration takes place either internally in our laboratory in Opava or externally at the customer’s premises. Part of our service to our customers, in addition to calibration of measuring instruments and calibration of measuring devices, is the measurement of non-conforming dimensions in products, collection/importation/delivery of measuring instruments for calibration and after calibration, mediation of purchase of new measuring instruments and service of measuring instruments.

Calibration of measuring instruments - length and plane angle

Technical security, equipment, precision of instruments, successful projects and educated staff with experience in technical fields guarantee high quality in the services offered and operated. The environment in which the instruments are calibrated is important for reliable and trustworthy calibration. Our calibration laboratory is monitored and equipped with a powerful air conditioning system to ensure the required humidity and ambient temperature (20 °C).

Gauges, measuring instruments, calibrators, measuring systems, measuring scales can be prone to deviations and loss of accuracy over time.

Regular calibration mode for gauges

It alerts you in time to inconsistencies in the measured values and generates non-compliant meters. The entire calibration process is electronically managed. Calibration sheets are printed or, with your consent and a unique password, are stored in the cloud/storage where you can store and generate calibration sheets, requests or orders.

Calibration of measuring instruments is a technical operation that specifies the metrological properties of the calibrated measuring instrument. An accredited calibration will guarantee the continuity, uniformity, correctness and accuracy of measurements that result from the Metrology Act.

Reference standards are calibrated by a superior authority (Czech Metrology Institute) for our use and subsequent guaranteed continuity. Standards are measuring instruments and measuring devices that are used to compare and transfer measured values.

Calibration of measuring instruments is necessary in many industries today. The most commonly calibrated gauges are for the engineering, transportation, construction, automotive and medical industries. Here are some specific examples of gauges that we calibrate:

- Gauge blocks 0–100 mm, 100–500 mm, up to 1 000 mm

- Comparators for calibration of gauge blocks, calibrators

- Sets of cylindrical pin (plug) gauges

- Pin / Plug / Ring / Snap / Thread / Cylindrical / Taper plain gauges

- Digital/analog/test/ dial gauges

- Analog/digital calipers and micrometers

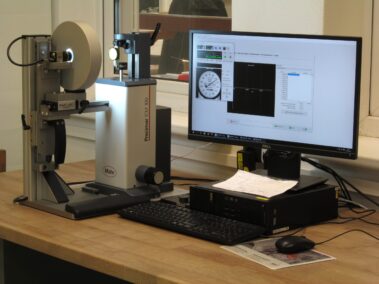

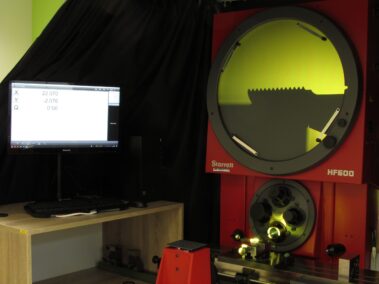

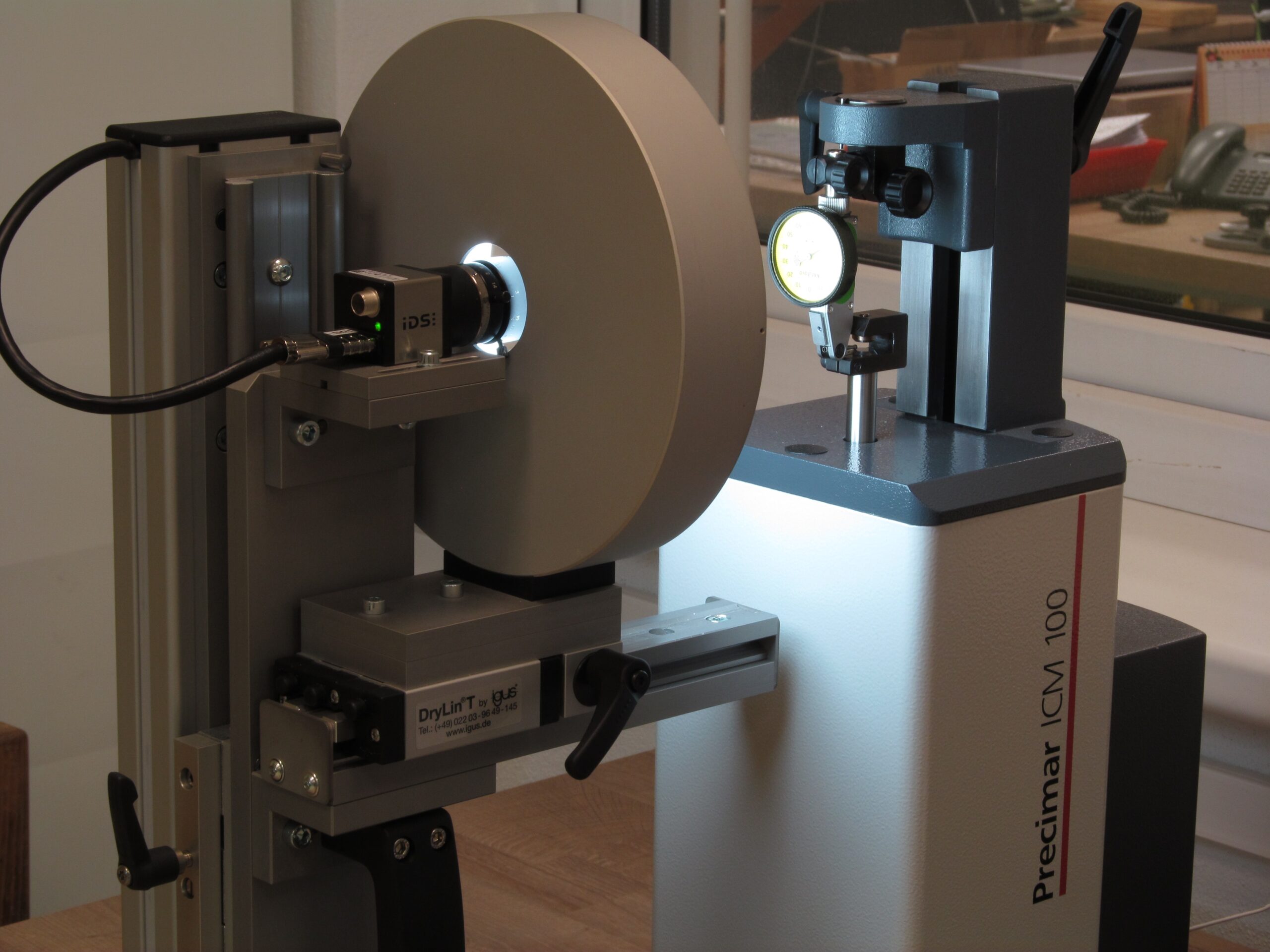

- 2D devices, length measuring machines, microscopes, Keyence profile projectors

- Electronic linear height gauges, height micrometers

- Granite surface plates, granite squares, cast iron straight edge rulers

- 3D coordinate measuring machines, calibration spheres

- Lens micrometers (glass scales)

- Roughness gauges, profilometers, roughness standards Ra, Rz, Rt…

- Spirit levels, cross line laser spirit levels, electronic spirit levels

- Measuring tapes (rules), Measuring wheels (walking measure)

- Laser distance meters

- Weld gauges, thread pitch (screw) gauges

- Radius gauges, Feeler gauges

- Angle gauges, Protractors, Flat edge squares

- Sine bar, sine cross tables

- Laser/electronic measuring probes (sensors) (TESA, KEYENCE…)

- Electronic display units (TESA TT10, TT80, TT90)

As far as calibration times are concerned, these are only recommended. It is up to you which validity period you choose for the calibration. Before you decide you need to think about two important factors in determining the validity period of a calibration – the environment in which the meter is located and the frequency of use.

We look forward to your visit, we are part of quality production and your development.